Mechanical Engineering Student Publications

Document Type

Article

Publication Date

8-1-2011

Abstract

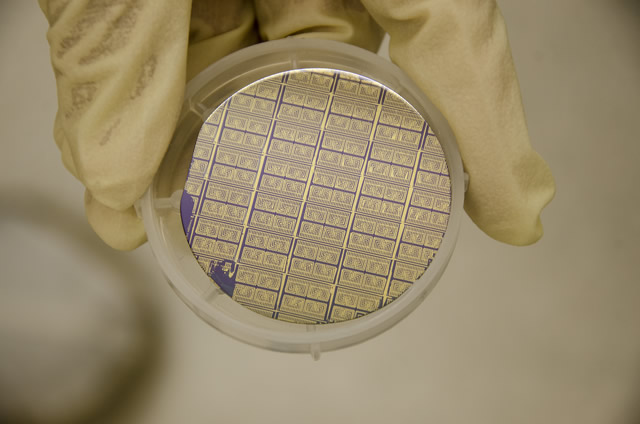

In engineering at LANL, everything relies on the quality of a product or process. Today dimensional inspection is a necessity to ensure customer specifications are met to the highest standard. Currently LANL’s main processes for dimensional inspection on hemi-shells are conducted on uniquely designed machines - Sheffield or Shell Measuring Machine (SMM). These specialized rotary contour machines were built to measure only the wall thickness, inner and outer contours of a hemi-shell. These machines are heavily dependent on the inspector and typically have very few personnel trained to use them. With no manufacturer support and age leading to production down time, this leads LANL to exploring other, newer technologies to support future endeavors. LANL has currently invested in newer technologies to account for these problems. Coordinate Measuring Machines (CMM) are a staple in the manufacturing engineering realm at LANL. CMMs utilize newer off-the-shelf technology, require less inspector involvement and can support a variety of different geometrically shaped parts produced at LANL. LANL, like all government funded laboratories, must use calibrated instruments for working processes. All measurement instruments must follow standards traceable to the National Institute of Standards and Technology (NIST). A Gauge Repeatability and Reproducibility (GR&R) study is utilized to ensure that the PMM-C LANL currently has in production is measuring correctly by utilizing measured data from a hemi-shell’s radial wall thickness and analyzing it for total process variation. The GR&R will also indicate to LANL if the PMM-C is passing a 4:1 measurement uncertainty ratio from general requirements of government specification 9900000. This report states that the PMM-C that is used in the GR&R study did meet ≤ 10% total process variability for the pole, midpoint and equator locations of a hemi-shell. The PMM-C also met and surpassed the 4:1 measurement uncertainty ratio utilizing the inner contour tolerances of the hemi-shell which was well under the 25% testing accuracy need to conduct production work at LANL.

DOI

LA-UR 11-02559

Language (ISO)

English

Sponsorship

LANL

Recommended Citation

Valdez, Lucas. "Gauge Repeatability and Reproducibility Study on a Hemi-shell with a Brown & Sharpe® Coordinate Measuring Machine (U)." (2011). doi:LA-UR 11-02559.